Innovative Design for Modern Challenges

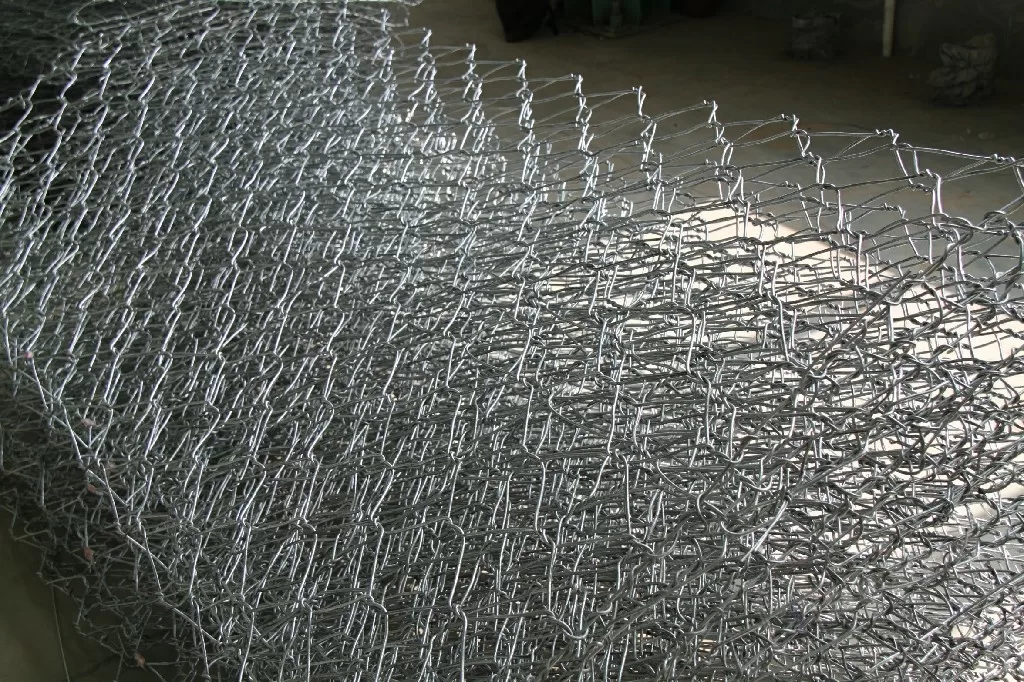

Engineered with high-grade galvanized steel wire in a double-twisted hexagonal configuration, these gabion baskets deliver exceptional tensile strength and flexibility, making them ideal for dynamic environments requiring structural integrity and adaptive solutions. The corrosion-resistant zinc-aluminum alloy coating (215–275 g/m²) ensures decades of performance in coastal, riverine, or industrial settings where traditional materials degrade rapidly.

Precision Engineering Meets Natural Aesthetics

Available in modular dimensions (1.5m–4m lengths) and wire diameters (2.0–3.9mm), the system accommodates site-specific requirements while maintaining an 80×100mm or 100×120mm mesh density (±16% tolerance). When filled with locally sourced 4–8” (100–200mm) angular stone, the units create permeable barriers that harmonize with ecosystems, reducing hydrostatic pressure by 40% compared to solid walls while supporting vegetation growth.

Transformative Applications Across Industries

Urban Infrastructure: Stabilize highway embankments with interlocking gabion tiers that absorb vibration from heavy traffic.

Water Management: To dissipate hydraulic energy, construct stepped weirs in flood channels using diaphragm-reinforced units (0–3 partitions).

Coastal Defense: Deploy staggered gabion revetments that self-adjust to tidal forces, reducing erosion by 60% in 3-year field trials.

Landscape Architecture: Craft curvilinear retaining walls with on-site bendable baskets, blending engineering with artistic terrain sculpting.

Smart Installation & Sustainability Features

Pre-Assembled Kits: Reduce construction timelines by 35% with foldable units requiring minimal onsite labor.

Carbon-Neutral Option: Specify recycled aggregate fills to achieve LEED certification points for sustainable material usage.

Monitoring Integration: Embed strain sensors within critical baskets for real-time stability tracking via IoT platforms.

Technical Validation & Compliance

Third-party testing confirms:

25 kN/m² load-bearing capacity under AS 3700 standards

0.02% annual zinc coating loss in salt spray tests (ASTM B117)

Full ASTM A975-97 compliance for civil engineering applications