Material Delivery

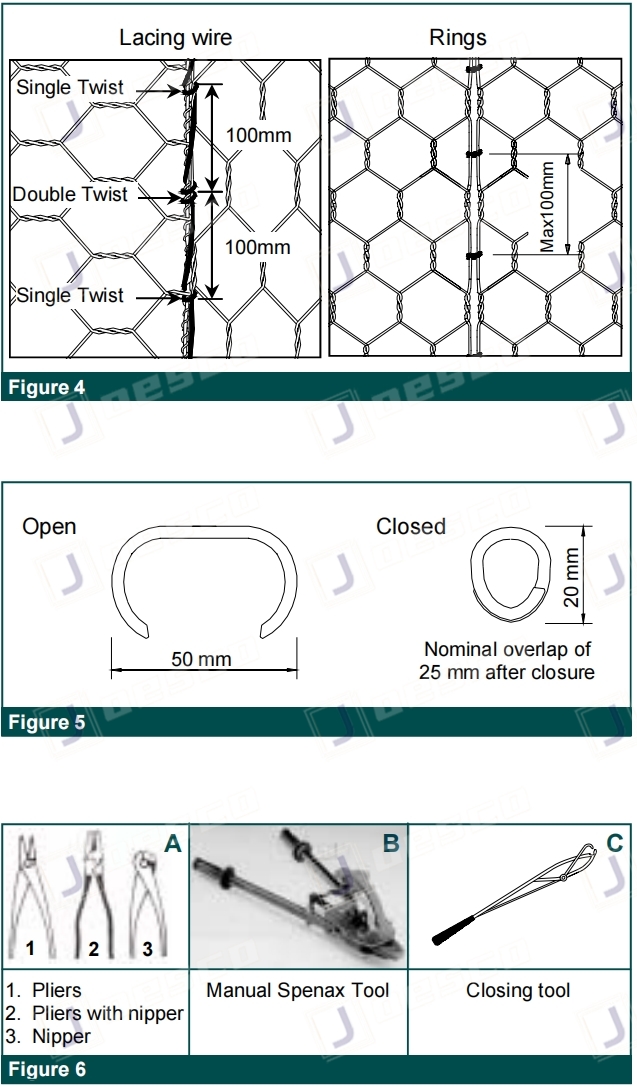

Sack Gabions are manufactured with all components mechanically connected at the production facility. All Sack Gabions are supplied in the collapsed form, folded and bundled. The bundles are compressed and strapped together at the factory for easy shipping and handling. Lacing wire is supplied in coils. Ring fasteners(Figure 5) are shipped in boxes that must be stored in a dry environment.

Assembly

The folded Sack Gabion units shall be taken out from the bundle and placed on a hard flat surface. They shall be opened, unfolded, and pressed to their original shape ready for assembly.

Foundation preparation

The foundation on which the Sack Gabions are to be placed need not be leveled and graded as Sack Gabions are used to provide a firm platform in areas where poor founding conditions exist or in areas where founding occurs in the wet. Appropriate measures shall be taken for the separation of the foundation layer from the rock-filled Sack Gabion by the project specifications (geotextile, drain works, etc.).Geotextiles required to be installed behind or underneath the Sack Gabion structures shall comply with the requirements of the project specification.

Lacing

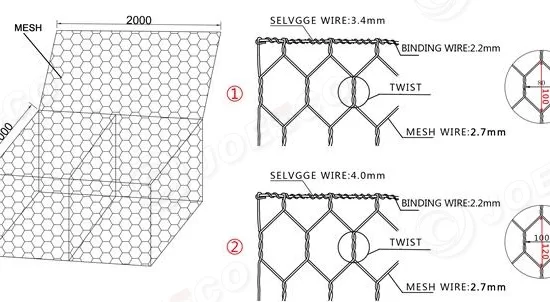

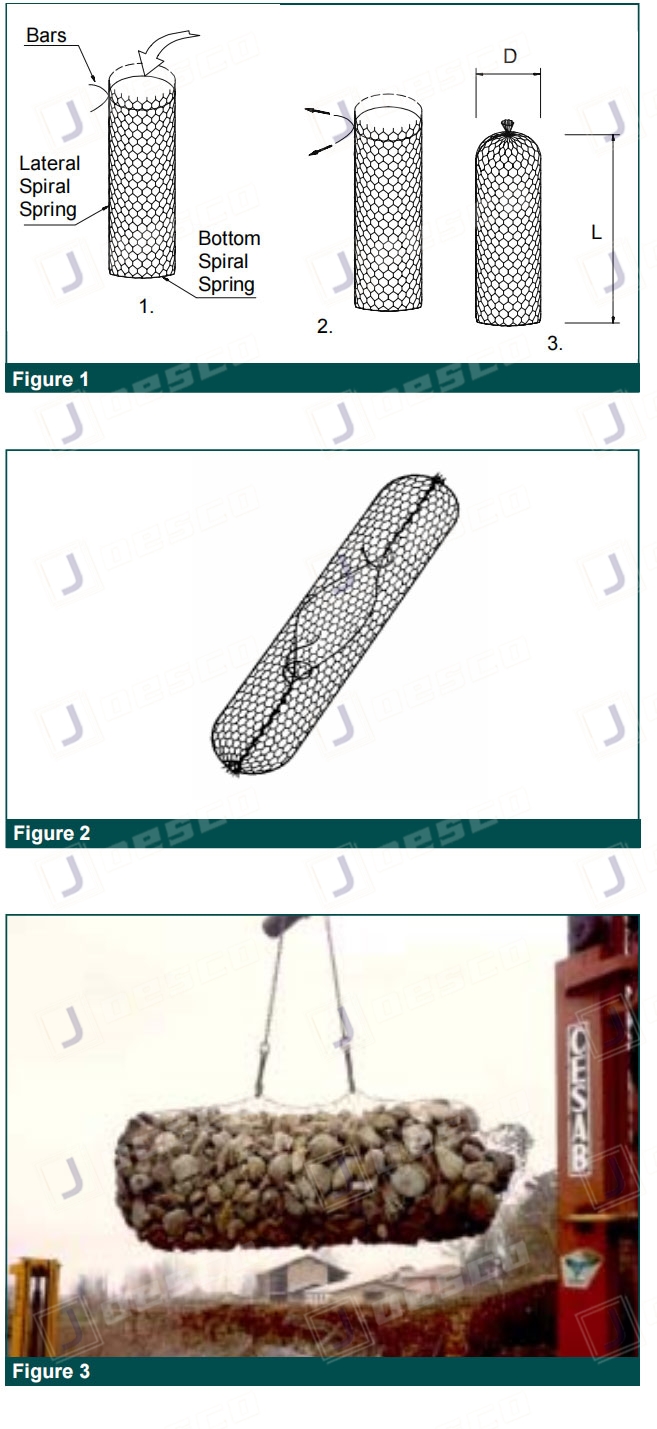

Sack Gabions are assembled by rolling the mesh panel into a cylindrical shape and overlapping the selvedged edges. By pulling and tightening the lateral spiral wire, the edges are secured. Excess spiral wire shall be secured around the selvage wire by looping and twisting the wire around itself. Once the longitudinal overlap is secured, the one end of the cylinder can be laced closed. This is accomplished by pulling the two ends of the bottom spiral tightly together and securing by again looping and twisting the wire around itself (Figure 1). Care shall be taken to avoid damaging the wire coating. The remaining end of the cylinder is left open to allow the Sack Gabion to be filled with suitable stone.

Installation and Filling

Rocks for Sack Gabions may be produced by any suitable quarrying method and by the use of any device that yields the required sizes within the gradation limits chosen. Rocks shall be hard, angular to round, durable, and of such quality that they shall not disintegrate on exposure to water or weathering during the life of the structure. Rocks shall range between 100 mm and 200 mm. The range in sizes may allow for a variation of 5% oversize and/or 5% undersize rock, provided it is not placed on the exposed surface. In all cases, the oversize rock shall not be larger than 250 mm, and the undersized rock shall not be smaller than 80 mm.

Rock shall be placed from the open end of the cylindrical-shaped gabion. Once the Sack Gabion has been filled satisfactorily, the ends of the top spiral wire are pulled tight, twisted, and looped onto itself. Care shall be taken when placing the stone to avoid damaging the wire coating. Hand manipulation of the rock may be necessary to minimize voids and achieve a maximum density of the rock in the Sack Gabion.

Placement

To facilitate placement, Sack Gabions can be placed individually or in pairs, provided they are laced together. When lifting SackGabions, care should be taken to lift the Sack Gabion by the thicker overlapped selvage wires (Figure 3).