Material Delivery

Green Terramesh units are supplied in the collapsed form,

folded and bundled. The bundles are compressed, strapped, and wrapped with plastic at the factory for easy shipping and handling. Each bundle is labelled with a tag reporting the sizes of the units contained. Lacing wire is supplied in coils. Ring fasteners (Figure 4) are shipped in boxes which must be stored in a dry environment.

Assembly

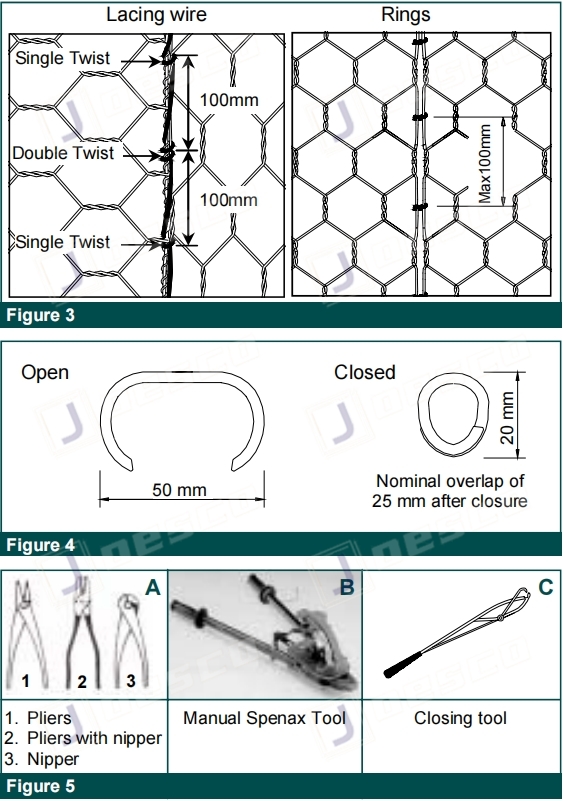

The folded units shall be taken out from the bundle and placed on

a hard flat surface. Green Terramesh units shall be opened,

unfolded and pressed to their original shape. When the units are unfolded for assembly, they will have one or two shipping folds. They can be removed by placing the fold over a board and walking along the sides.

Fixing Procedure

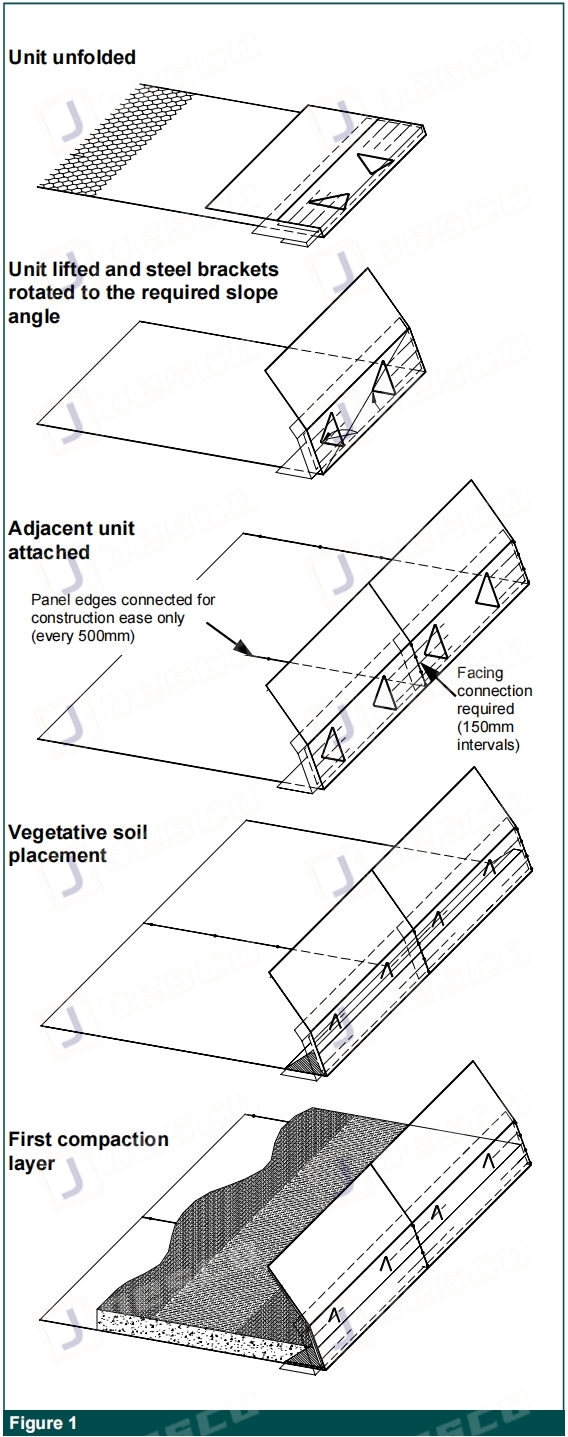

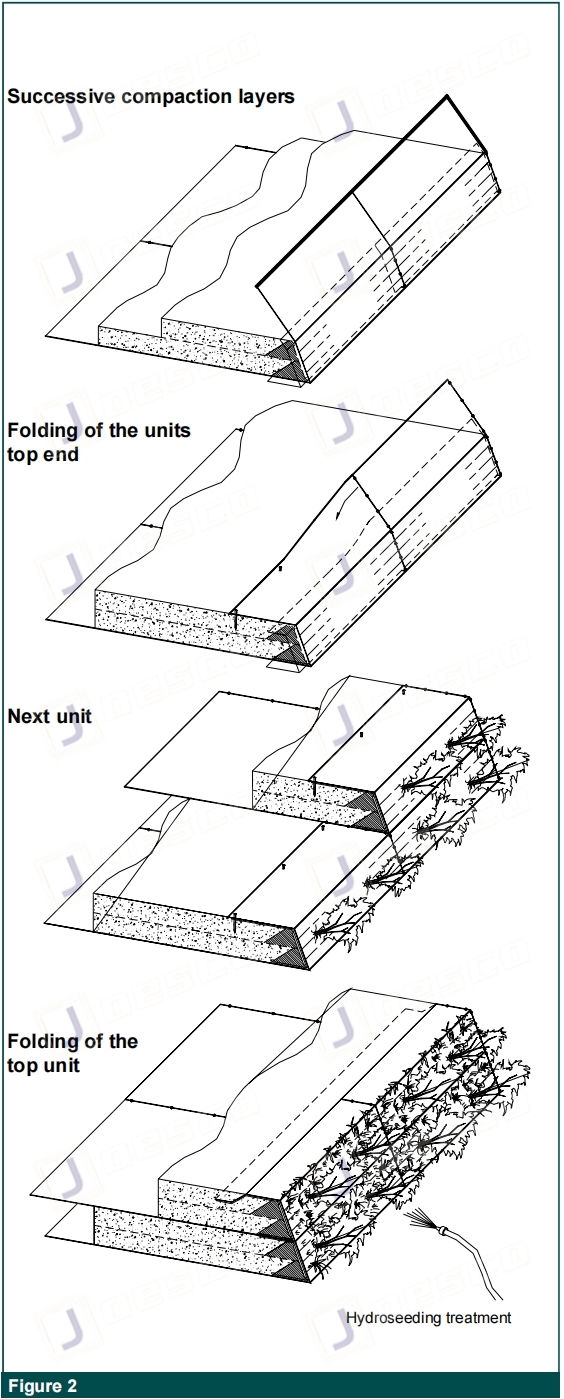

When using lacing wire, cut off a piece of wire approximately 1.5 times the length of the edge to be tied. The maximum length of the edge to be tied at one time shall not exceed 1 m. Longer edges shall be joined by several lengths of wire. Lacing wires shall be secured around the selvedge wire or heavier edge wire, where present, by looping and twisting the lacing wire around itself. Proceed tying with alternate double and single loops (Figure 3). Double loops shall be made at intervals not greater than 300 mm. All panels shall be pulled tightly together during the tying operation. Pliers (Figure 5) may be used to create tight joints. The other end of the lacing wire shall be secured by looping and twisting the wire around itself. When using lacing wire to assemble the units care should be taken to avoid damaging the wire coating. When steel ring fasteners are used, the custom-made Maccaferri Manual Spenax Tool (Figure 5) is required and available for hire. Rings shall be installed at the top and the bottom connections of the end and centre diaphragms and then a maximum spacing of 100 mm along all edges shall be used. Connect with ring fasteners between adjacent units. Connections made along the panel edges assure a flat surface for fill placement.

Foundation Preparation

The foundation on which the Green Terramesh units are to be placed shall be level and graded to the elevations as shown on the project construction drawings, and free of surface irregularities, loose material and vegetation by the project specifications.

Installation, Filling and Soil Compaction

After the foundation has been prepared, the pre-assembled Green Terramesh™M units shall be placed in position empty, and tied or fastened to adjacent units along all edges to form a continuously connected, monolithic structural unit. Units shall be placed in position according to the required slope angle. Triangular steel brackets shall be rotated and securely attached to the bottom of the main unit using conventional fastening tools(Figure 5) (lacing wire or rings). The erosion control blanket of each unit shall overlap for 100 mm with the adjacent unit blanket on the side in a manner to ensure that the vegetative soil behind will not be exposed at any time. Care shall be taken when placing the soil to avoid damage to the wire coating. After a layer of soil has been placed, sufficient hand shovelling shall be performed to achieve a uniform top surface before soil compaction is performed. Vegetative soil is placed behind the facing for about 0.5 to 0.6m.

Soil compaction within 2 m of the face should be carefully performed with a walk-behind compactor to prevent any slope distortion or bulging of the facing unit.

Place soil fill in approximately 300 mm lifts and compact it to the required level. Mechanically stabilised earth structures shall be made of good quality, free draining, granular and/or selected fill. The recommended soil gradation is in the range of 0,02 mm to 6 mm, or as indicated in the project specifications. Soils outside of this range may be suitable, providing they have been approved by a geotechnical engineer.

Compaction shall be performed to 95% of Standard Proctor, by use of conventional compaction equipment. The number of compaction and vegetative soil layers will be as such to achieve the required vertical spacing between the Green Terramesh units, according to the project specifications. Once the soil layers after compaction have achieved the top of the Green Terramesh unit, the top end is folded and securely stapled to the soil. Care shall be taken to ensure that all adjacent units (above, underneath and sideways)will be connected along the face at the contact edges.

The top return portion of the last unit on top of the structure shall be buried approximately 300 mm beneath the soil surface.

Hydroseed or plant, if needed, using a native species increases the chance of survival. Irrigation may be necessary in drier climates/seasons.